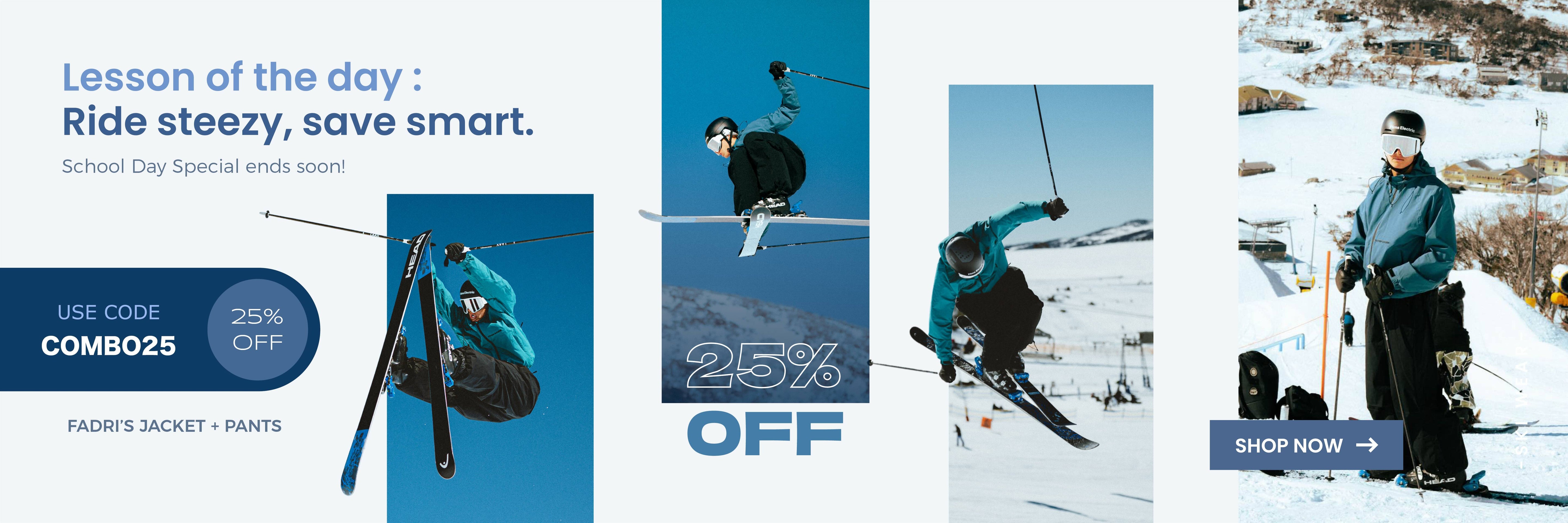

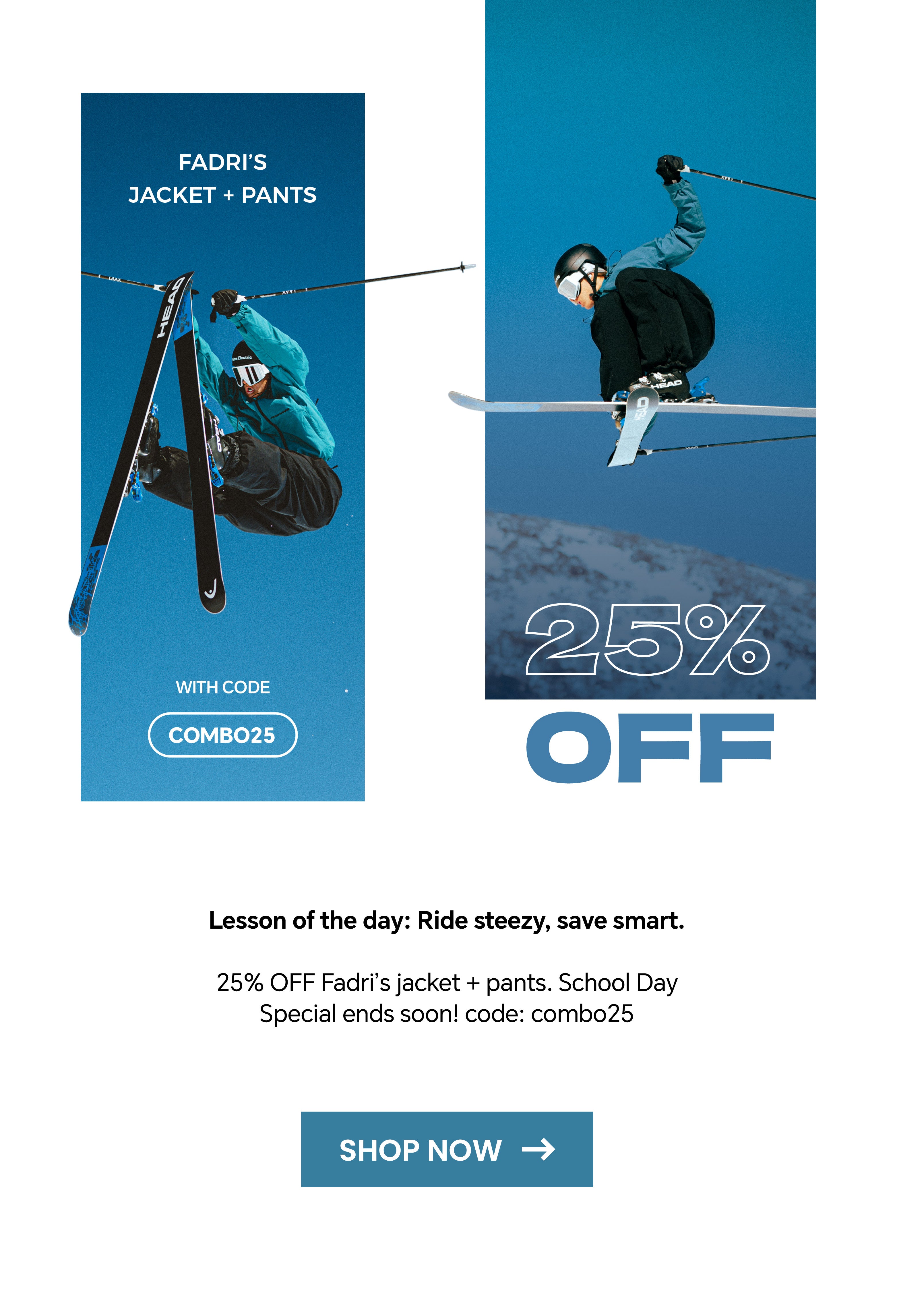

Special Offers - US/UK/CA/AU Only SAVE NOW

Shop Top Categories

Gear We Love

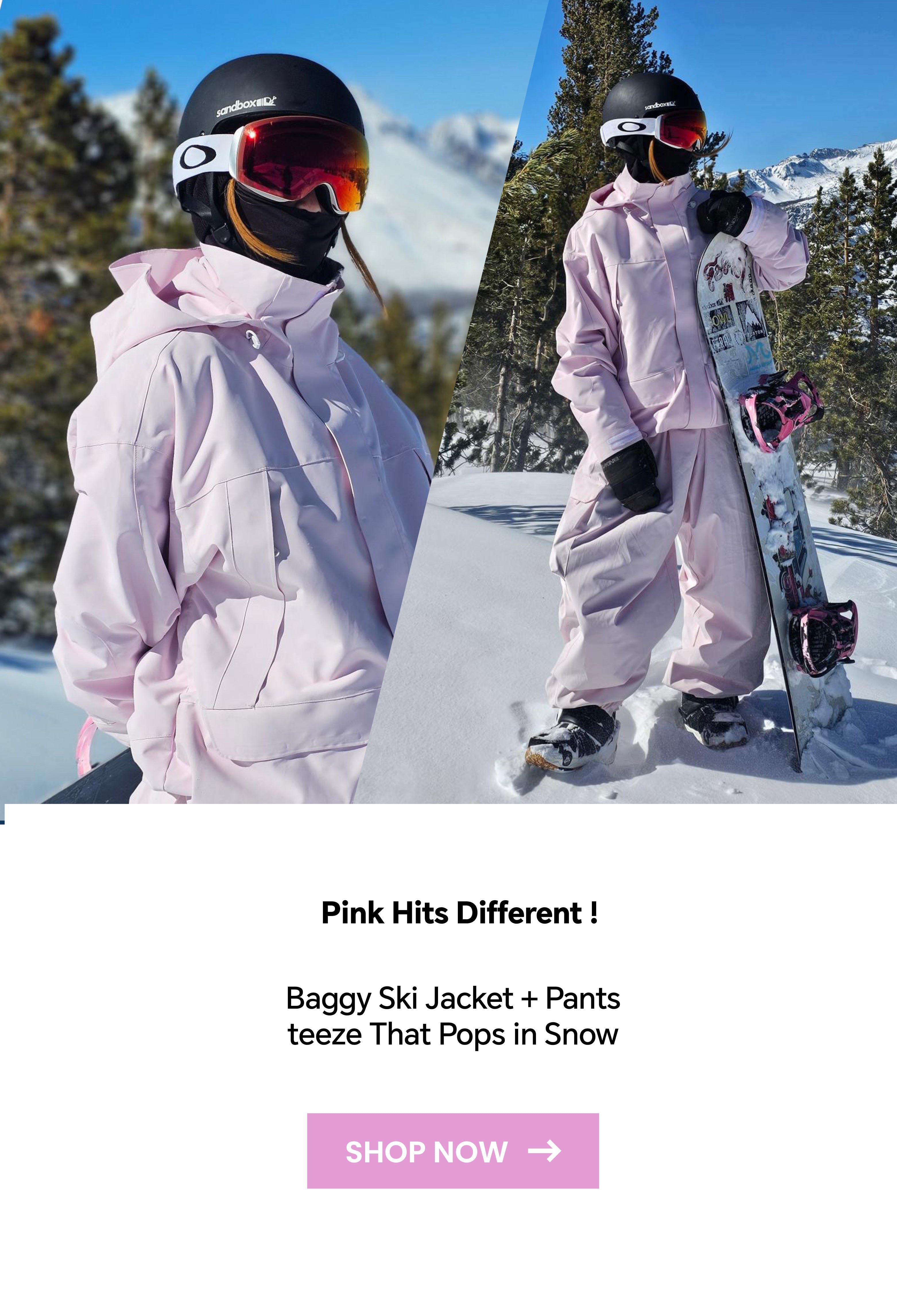

All-Terrain Baggy Ski Trousers

No cargo pockets, no power skirt-just lightweightcomfort for smooth park days.

Baggy Cargo Trousers

Best-Seller of the Year – Durable fabric, secure storage, and the perfect baggy fit.

Glideflow Shell Jacket

Long zippers for instant airflow and a drawstring hem for a customized fit.

Summer Essentials

Snowears Drop

Gear Reviews

FREE SHIPPING

Free shipping on all order above $99

SUPPORT 24/7

Contact us 24 hours a day, 7 days a week

30 DAYS RETURN

Changed your mind? You can return any non-clearance item within 30 days.

100% PAYMENT SECURE

We ensure secure payment with PEV

- 選択するとページ全体が更新されます。